Slots In Pistons Can Be Used For

- Slots In Pistons Can Be Used For A

- Slots In Pistons Can Be Used For Cash

- Slots In Pistons Can Be Used For Sale

- Slots In Pistons Can Be Used Forever

- Slots In Pistons Can Be Used For

The invention relates to the field of engineering, including the engine construction, engineering, pump engineering turn out and so on, and can be used in volumetric machines, which convert the energy of the working fluid - liquid or gas, for example, in a rotary-piston internal combustion engines with cycles type Otto, Diesel or trochoidea engines of the Wankel type. Insufficient clearance can cause the piston to seize in the cylinder. Excessive clearance can cause a loss of compression and an increase in piston noise. Piston features include the piston head, piston pin bore, piston pin, skirt, ring grooves, ring lands, and piston rings. Holes or slots cut into the radial center of the ring allow the. The loss of piston clearance could lead to serious engine problems like excessive friction, excessive wear and at the end possible seizure of the piston in cylinder leading to complete engine failure. It has become absurd at this point the regularity the Pistons pick in that slot, and its directly responsible for the terrible decade+ all of us have sat thru. Last lottery, #7 was the highest pick since Monroe at #7(2010!!!), and before that Darko at #2.(2003!) Think about how long this team has sucked butt, and that is the highest pick. Perhaps the most extreme example of the slotting method of quietening pistons is seen on the very old 803cc/850cc specimens where a 'T' slot was machined into one side of the piston skirt. Whilst not ideal, slots certainly aren't a huge problem where high performance is planned - providing the slots are not excessively long.

Piston parts, unlike designs and material, do not vary across different pistons. They remain the same with differences only in their sizes.

This article explores the automotive piston assembly components, detailing the function of each.

To make identifying each part easy, we added images in the descriptions.

Piston components extend all the way from the part bordering the combustion chamber to the end that connects to the crankshaft. Collectively, these parts make the piston assembly.

These are the components we will focus on. Before proceeding, here is a diagram showing all piston parts.

Now, on to a detailed description of each component.

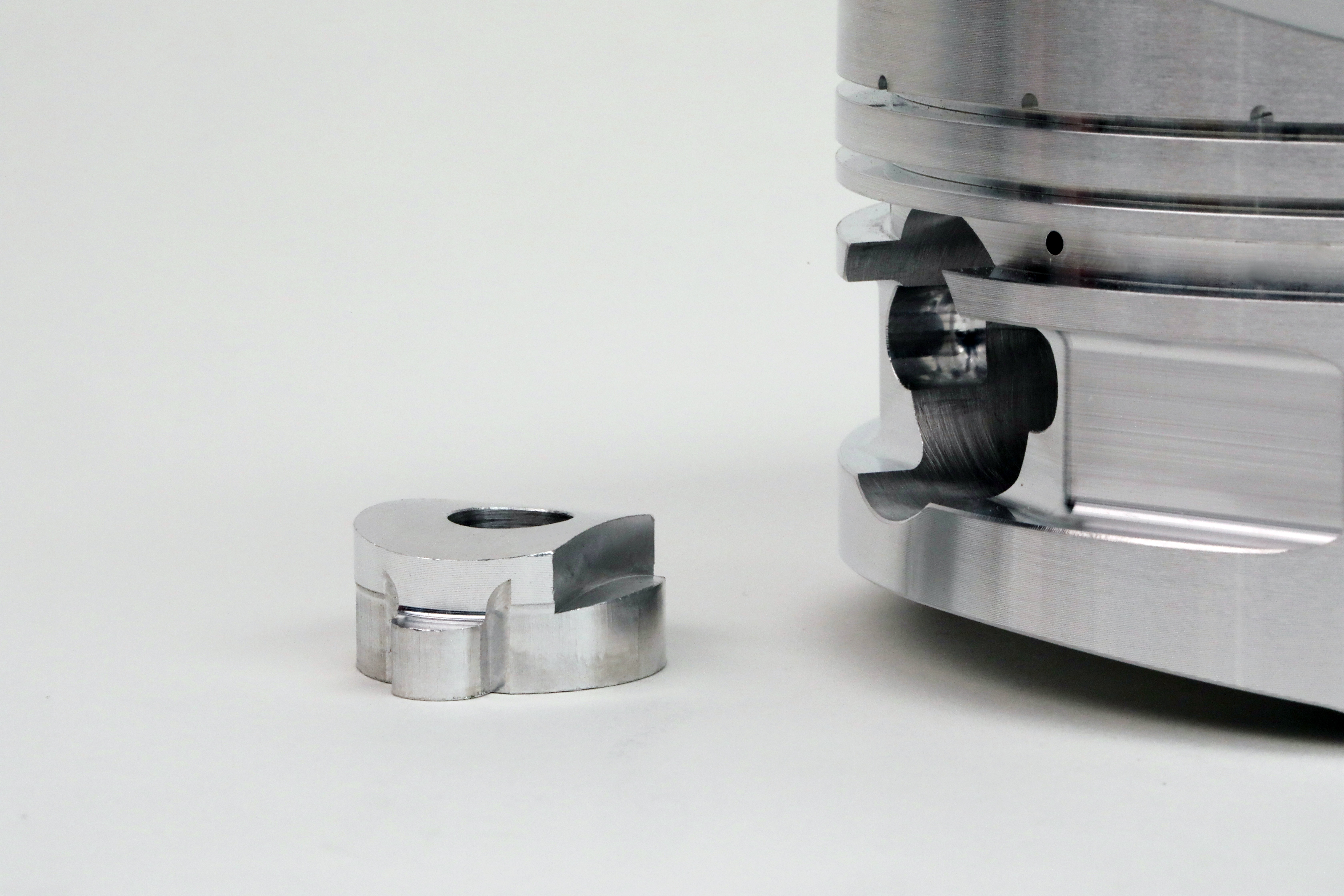

1. Piston Ring

Piston Ring Definition

Piston ringsare pieces of split rings that mount on a recessed area of the piston. Thereare usually 3 piston rings in a typical car engine. The number varies, and a pistoncan even have one ring. The areas or surfaces between these rings arecalled piston ring lands. The ring mounting grooves are designed to maintain the piston ring position, andyou may hear something like tapered construction.

The split design of the piston ring has several benefits. It allows for spring action, which helps the rings to maintain the correct piston ring gap. The split also makes piston ring installation easy. To ensure spring constant under heat, load, pressures, and other conditions, manufacturers prefer cast iron or pieces of steel for piston rings material.

Piston Ring Function

The primary function of piston rings is to seal off the combustionchamber and regulate lubricating oil usage. The rings also serve to conductheat away to the cylinderbore. As mentionedbefore, most vehicle engine pistons feature three rings; two upper compressionrings and a lower oil ring. For clarity, the different rings are explainedbelow.

- Compressionring– this is the top side ring and nearest the combustion chamber. It is also called the gas or pressure ring. The ring prevents combustion gases from leaking. Compression rings also help transfer heat from the piston to the walls of the cylinder.

- Scraper/wiperring– this is located between the compression and oil rings. It features a tapered surface and serves the function of both rings: to seal the combustion chamber and to wipe oil off the walls of the piston cylinder.

- Oilcontrolring– the piston oil ring is the lower ring on the piston. It consists of two thin surfaces, with holes all around. The slots allow oil to flow back into the sump. As its name suggests, the function of the piston oil control ring is to remove excess oil from the cylinder walls. It does that as the piston works back and forth.

2. Piston Skirt

Piston Skirt Definition

The skirt of a piston refers to the cylindrical material mounted on the round section of a piston. The part is usually made from cast iron material due to its excellent wear resistance and self-lubricating properties. The skirt contains the grooves to mount the piston oil ring as well as compression rings. Piston skirts come in different styles to suit specific applications.

Piston Skirt Function

The skirt guides the piston as it travels up and down the cylinder.Its design helps the pistonto overcome the side forces created by the changing angle of the connecting rod. If the skirt is worn, obtaining a proper pistonseal for efficientcombustion would prove difficult.

Thepiston would also rock in the cylinder uncontrollably and cause piston slap. When thathappens, you may hear the infamous piston slap noise, especially during cold starts. Piston slap willoften go away after the engine has warmed. That is because the resultingresulting expansion closes the gap between piston and cylinder.

Ifthe noise does not stop, the cylinder may need to be tightened, among othermeasures. Otherwise, the problem does not present much danger, and you maydrive your car if the noise only appears when starting the engine.

There are two main types ofpiston skirts:

- Full skirt

It is also known as solid skirt. The full skirt features a tubular shape. It is commonly used in the engines of large automobiles.

- Slipper skirt

The type of piston skirt is used on the pistons of motorcycles and some cars. It has part of the skirt cut away to leave only the surfaces on the back and front of the cylinder wall. This helps to reduce weight and minimize the contact area between the cylinder wall and the piston.

3. Piston Pin

Piston Pin Definition

Also known as wrist pin or Gudgeon pin, the piston pin is the hollow or solidshaft in the skirt section. The piston rod pivots on this pin, held in the piston ring bushing. For tensile strength, piston pins areusually built from alloy steel and machined to fit the piston bearing. Holes in the connecting rod deliver oil to the wristpin, helping to reduce friction.

Piston pin assemblies and mounting styles vary. They can be categorized into 3 designs: free to revolve in both piston and connecting rod, clamped to connecting rod, and rigidly mounted to piston bosses.

Piston Pin Function

A piston pin forms the connection or pivotal point of the pistons andconnecting rod. They provide bearing support and help pistons to functionproperly. In other words, the pin facilitates the back and forth movement ofthe piston.

As we have seen, piston pins use three methods to mount on the piston assembly. These give rise to the following types of pins.

- Stationary/fixedpin– the pin attaches to the bosses of the piston via a screw. The piston rod then pivots on the pin.

- Semifloating– the pin attaches to the connecting rod in the middle, and the pin ends move freely within the piston bearing and at the bosses.

- Fullfloating– in this pin type, the pin is not attached to the pin or piston connecting rod. Instead, it is secured by plugs, clips, or snap ring attached to the piston bosses. The pin can then oscillate at the bosses as well as the rod.

4. Piston Head/Crown

Piston Head Definition

Slots In Pistons Can Be Used For A

Also known as the piston crown or dome, the headof a piston is its top surface. It is the part that comes into contact with thecombustiongases. As a result, itgets heated to extremely high temperatures. To prevent melting, piston head parts are made using special alloys, among them steelalloy.

A piston head is usually built with channels and cavities. These help to create a swirl that improves combustion. Different piston head types are used in different engines. Reasons for the differences vary. The preferred piston head design depends on many factors, such as expected performance and engine type.

Piston Head Functions

The crown, as it is also known, forms the surface that takes in thepressures, temperatures, and other stresses of the expanding gases. Among thepurposes it serves are:

- Creating swirl to make combustion uniform and regulate knocking

- Act as a heat barrier between the combustion chamber and the lower piston parts

- Contain the pressures resulting from knock in the cylinder

5. Connecting Rod

Connecting Rod Definition

Often shortenedto conrod or rod, the connecting rod is one ofthe most important piston parts. It links the piston to the engine’s crankshaft and movesthe piston in and out of the combustion chamber. Connecting rods have to bear alot of mechanical strain and should be sturdy enough. For this reason, theparts are mostly forged, although casting is also frequently used.

Automotive piston manufacturers often prefer steel to manufacture these rods. Alloy steel is also a popular conrod material, especially for high-performance engines. For milder engines, aluminum may be preferred for its lightweight nature. The rods of small engines such as scooters can even be made from iron.

Connecting Rod Function

Theconrod rotates the crankshaft, producing the motion that enables a vehicle tomove. In some engines, the piston rod features a hole or bore to deliver lubricating oilto the cylinder walls and wrist pin. Manufacturers make conrods in variousdesigns. Versions include cracked joint, milled joint, straight and angledseparation rod, and the parallel and tapered rod design.

Theconnecting rod is divided into several parts. They are:

- Smallend– it is the smaller end of the rod. It consists of the rod eye and piston bushing. The small end links to the piston via the piston pin.

- Bigend– the big end is the part opposite the small end of the conrod. It connects to the crankshaft and features a slit design to allow it to be mounted.

- Connectingrodbeam– this is the section between the small and big parts of the rod. Usually a double T construction, the beam may or may not contain an oil bore to channel lubricant to the cylinder.

6. Connecting Rod Bolt

Connecting Rod Bolt Definition

Alsoin the list of piston parts is the conrod bolt. These bolts clamp the rod to thecrankshaft. The bottom end of rod bolts bolt are rod caps and bearings, held inplace by a nut. A cotter pin on the nut prevents the assembly from comingundone.

Conrod bolts are usually made from steel. In applications where weight reduction is an essential feature, aluminum bolts care common. The rod can also be made from nickel. Nickel connecting rod bolts are stronger and mostly used in heavy-duty rods.

Connecting Rod Bolt Function

Aswe have seen, the bolts secure the connecting rod to the crankshaft. They helpthe rod to withstand the strain caused by the rotating crankshaft. In theirabsence, the rod would break down affect the working of other engine parts. The rods guide every pistonstroke, ensuring smooth engine operation.

Conrodbolts are made with the ability to bend a little under the action of the piston and crankshaft movements. Thatprotects the rod caps from collapsing due to the extreme strain caused by themoving crankshaft and piston.

Connecting rod bolts come in a variety of designs. They can be hexagonal, round, flat or an embossed design. Some come threaded others unthreaded. Threaded bolts make the best parts due to their firmer grip.

7. Piston Bearings

The bearings are piston parts that are locatedat the points where pivotal rotation takes place. The are usually semicircularmetal pieces that fit in the bores of these points. Piston bearings include theshells found at the big end where the rod connects to the crankshaft. There arealso bearings at the small end where the rod links to the piston.

Piston bearings are usually manufactured using composite metals like lead copper, silicone aluminum, and others. The bearings are often coated to improve hardness and enable them to bear the load of piston and connecting rod movements.

Piston Parts Questions

1. Do engine pistons havereturn springs?

No, they do not. A piston return spring is not required in these pistons. However, you will find the springs in drum brake assemblies. Here, they help to retract the brake shoes when you release the brake pedal.

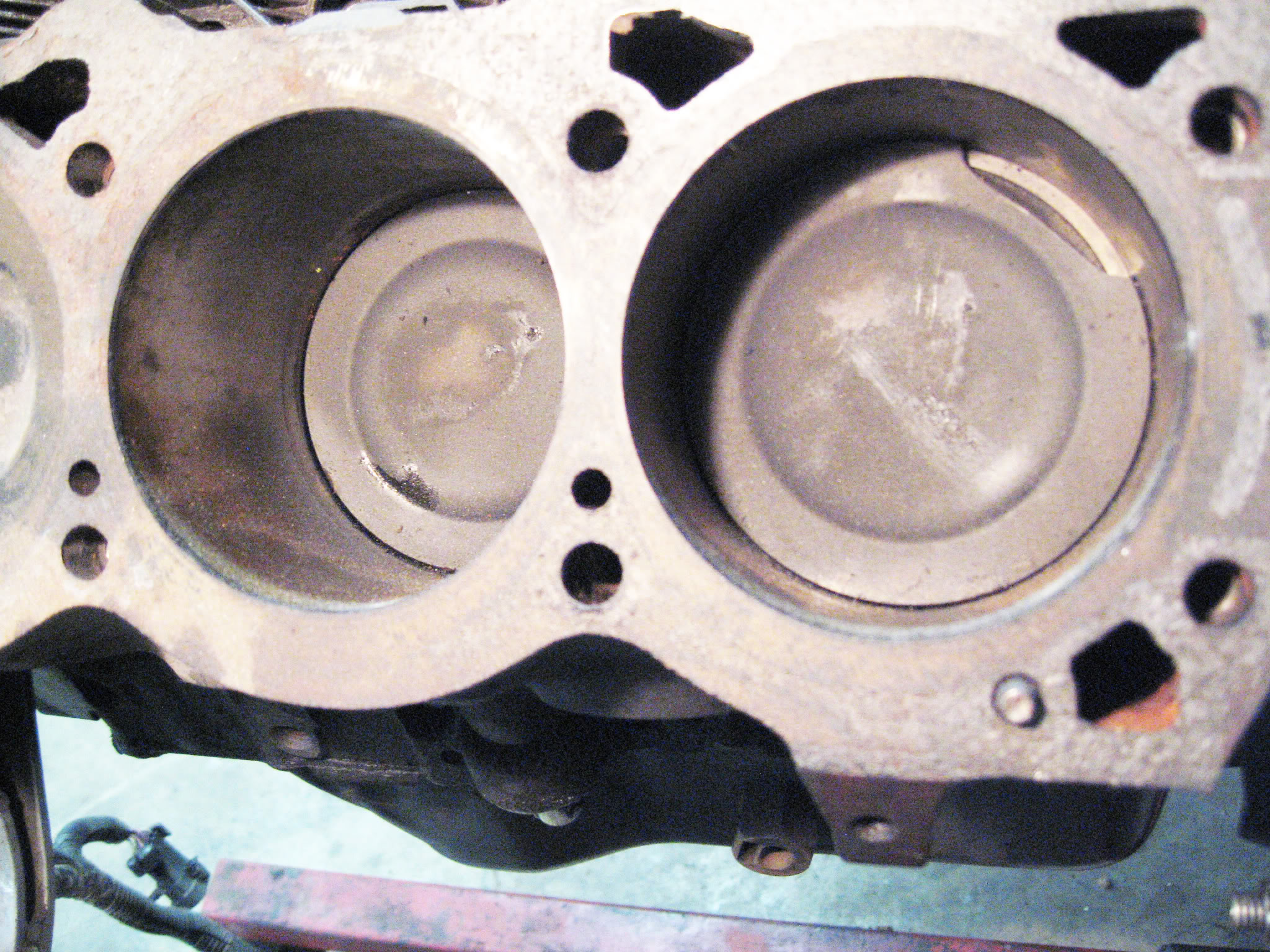

2. What is pistonliner?

It is a kind of liner installed on the walls of an engine cylinder.Usually made of superior material than that of the cylinder bore, the linerprovides a hard-wearing surface. Car owners install it to either protect thecylinder or repair it when rebuildingthe engine.

Because the liner is replaceable, using it increases engine life. A piston liner is also called piston sleeve and does not form part of piston assembly. You will also find it going by the name cylinder liner or sleeve.

3.What piston parts canbe replaced?

Most piston assembly components can be changed. They include piston rings, piston bearings, piston rod bolts, and several other parts. Thesecan be purchased individually or as a piston kit.

Slots In Pistons Can Be Used For Cash

Piston rings wear quickly. They are one of the most replaced piston parts. When damaged, these rings cause various piston and engine problems. That can lead to extra costs. Given that the piston ring price is only a few hundred dollars, replacing these parts can save you from expensive repairs.

4. What is the cost ofreplacing pistonparts?

The amount can exceed $1000 or even $2000. Piston kit price or that of individual components may be low, but notso the amount you pay a mechanic to do the job. Replacing anything hiddenwithin the engine block involves several hours of work, which iswhy it costs a lot.

Add that to the fact that there is usually a pistonset to change, and the amount can be pretty high. You canchoose to replace the piston or piston parts yourself, of course. However, youwould need the right tools, which include the following:

Slots In Pistons Can Be Used For Sale

A piston ringcompressor to install therings, a micrometer to pistonmeasurement, and a feelergauge set to measure piston and piston ring clearance. You may also need a piston ringfiler to hone the rings to thecorrect specifications. You also need to understand how to replace the pistoncorrectly. (we have a whole article dedicated to piston installation process). There are many piston types on the automotive piston market.

To find the right one for your engine, scour the websites of manufacturers. They usually provide an automotive pistons catalog. These contain invaluable information regarding the specific piston you may be looking for. That includes piston size chart for piston to cylinder clearance, piston depth chart, and more. You will also have the chance to piston price across sellers.

Slots In Pistons Can Be Used Forever

Conclusion

Slots In Pistons Can Be Used For

Havinglooked at piston parts,you now know how eachcomponent looks like as well as its location on the piston assembly. We have more articles on the automotive piston and youcan browse through them. The articles cover several topics, including piston measurement when rebuilding your engine. And iflooking for the right piston for your car engine, we have a full-length articleabout piston types.